ERME

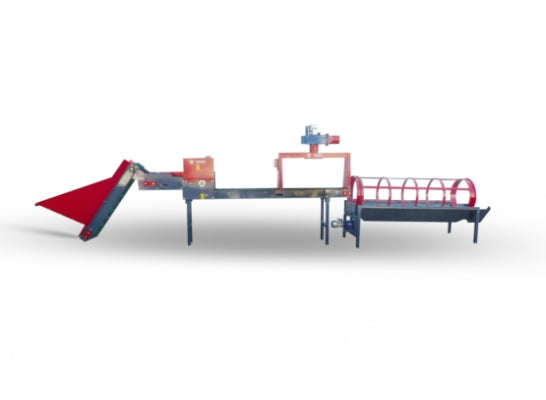

Garlic splitter ERME E150

Garlic splitter ERME E150

Couldn't load pickup availability

The ERME E150 garlic clove separator is a professional machine with a capacity of 150-200 kg/h. It features a conveyor with a 150 kg hopper, a soft belt separation system with a movable rubber plate, six rubber stars, and a skin extraction unit. It also includes a manual finishing belt for 2-4 people and a drum for calibrating cloves in four stages (<10 mm, 11-17 mm, 18-23 mm, >23 mm). The machine operates on a 380V power supply (optional 220V) with a total power of 1.70 kW.

Product Features

The ERME E150 garlic clove separating machine is a specialized device designed for professional garlic processing.

Features a complete system for separating garlic bulbs into cloves while maintaining their quality.

Equipped with a feed conveyor with a 150 kg capacity hopper (can be expanded upon request).

Uses an innovative separating mechanism consisting of a soft belt and a movable rubber plate.

Includes six rubber stars to assist in completing the separating process.

Equipped with a suction system that removes skins and debris, leaving clean cloves.

Equipped with a conveyor belt that allows 2-4 workers to manually complete the separation.

Includes a drum that calibrates cloves in four dimensional stages.

Available with a 380V (standard) or 220V (optional) power supply.

Can be customized to suit individual user needs.

Benefits Product

Implementing the ERME E150 machine in the processing process brings a number of tangible benefits:

- Processing capacity of 150-200 kg/h meets the needs of small and medium-sized processing plants.

- Automation of the garlic clove separation process significantly reduces manual labor.

- A 0.55 kW skin and debris suction system ensures the purity of the final product.

- A precise clove calibration system in four size categories allows for product standardization.

- The possibility of engaging 2-4 people for manual finishing ensures optimal quality control.

- The system's flexibility allows for the processing of various garlic varieties and sizes.

- An innovative separation mechanism minimizes damage to the cloves during the process.

- A 150 kg capacity hopper ensures continuous operation.

- Low energy consumption (total power 1.70 kW) translates into economical operation.

- The availability of a 220V version expands the machine's application possibilities.

Technical Specifications

Machine Type: Garlic Machine Separating garlic bulbs into cloves

Model: ERME E150

Total power: 1.70 kW

Power supply: 380V three-phase (optional 220V version available)

Capacity: 150-200 kg/h

System components:

Infeed conveyor:

Gearbox: 0.37 kW, 380V

Feed hopper: 150 kg capacity (larger available upon request)

Separation unit:

Belt with a rubber-coated top plate adjustable to various degrees

Six rubber stars to support the separation process

Suction unit:

Power: 0.55 kW, 380V three-phase

Adjustable suction power for skins and debris

Conveyor belt for manual finishing:

Workstations for 2-4 people

Tooth calibration drum:

Level 1: less than 10 mm

Level 2: 11-17 mm

Level 3: 18-23 mm

Level 4: greater than 23 mm

Want to order?

Featured collection

-

Garlic planter AGP-4R_W GARMACH

Regular price $0.00 USDRegular priceUnit price / per -

5-ROW chain garlic planter GARMACH AGP-5R

Regular price $0.00 USDRegular priceUnit price / per -

4-ROW chain garlic planter GARMACH AGP-4R

Regular price $0.00 USDRegular priceUnit price / per -

Garlic planter AGP-3R GARMACH

Regular price $0.00 USDRegular priceUnit price / per