Garmach

Two-row potato planter S239

Two-row potato planter S239

Couldn't load pickup availability

Two-row potato planter S239

The S239 two-row potato planter is a modern agricultural machine with a three-point linkage (CAT II three-point linkage). It performs all operations in a single cycle: digging furrows, automatically planting potatoes, and shaping ridges. The S239 two-row potato planter makes furrows, automatically seeds, and covers potatoes in a single pass, providing full automation of the planting process. It allows you to plant in rows of 62.5/67.5 cm (S239 model) or 70/75 cm (S239/1 model) and adjust the spacing between seed potatoes (29, 32, or 35 cm) by changing the diameter of the ground wheels. It is offered in two versions: the standard (180 kg hopper, 210 kg weight, 28 kW/38 HP power requirement) and the larger S239/1 (300 kg hopper, 220 kg weight, 32 kW/43 HP power requirement).

2 row potato planter

-

The S239 two-row potato planter is an advanced agricultural machine that:

-

Equipped with a three-point hitch compatible with tractors equipped with a CAT II system for standard tractor equipment

-

Performs all necessary operations in a single work cycle: makes furrows, automatically seeds, plants potatoes, and covers them with soil in one pass

-

Creates uniform ridges, ensuring optimal growth conditions for plants

-

Enables operation in row spacings of 62.5/67.5 cm in the standard S239 model or 70/75 cm in the S239/1 model

-

Offers adjustable seed potato spacing in a row: 29 cm, 32 cm, or 35 cm

-

Allows you to adjust the seed potato spacing by simply changing the diameter of the ground wheels

-

Available in two versions:

-

Standard S239 model with a hopper capacity of 180 kg and a weight of 210 kg

-

Extended S239/1 model with a hopper capacity of 300 kg and a weight of 220 kg

-

It is built for durability and adaptability to various planting needs, ensuring stability and precision during operation

-

It stands out for its high work efficiency thanks to the simultaneous operation of two rows

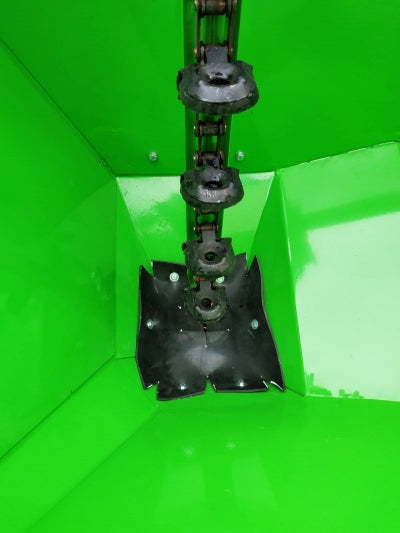

The means by which the S239 ensures precise seed spacing and planting depth include a combination of adjustable ground wheels, seed metering mechanisms, and corrector systems that guarantee consistent results. Each row unit can be adjusted or mounted to suit different row spacings, providing flexibility for various planting requirements.

Product Benefits

Using the S239 planter on your farm brings a number of tangible benefits: Significantly increased work efficiency thanks to the two-row design, which allows you to cover a larger area in less time. Saves time and labor costs by automating the entire potato planting process. High planting precision, resulting in uniform emergence and improved yields. Flexibility in adapting the machine to various cultivation systems thanks to the ability to select row spacing and seed potato spacing. Possibility to adjust operating parameters to the specific requirements of the potato varieties being grown. Optimal ridge formation, ensuring proper growth conditions for plants and facilitating subsequent harvesting. Large hopper capacity (especially in the S239/1 model) minimizes the need for frequent refilling. Seed Potato Planter compatible with popular tractors equipped with a CAT II three-point linkage. Sturdy construction guarantees long-term operation and reliability. Improved crop quality thanks to even seed potato distribution and proper soil coverage. The planter can be supplied with a set of interchangeable parts, and two sets of trays and wheels are available for customization. Additional sets of components (such as trays or wheels) can be ordered to enhance functionality.

Type: Two-row potato planter

Models:

S239 (standard)

S239/1 (extended)

Operating Parameters:

Row width:

625/675 mm (S239 model)

700/750 mm (S239/1 model)

Seed potato spacing in a row: adjustable 29 cm, 32 cm, 35 cm

Spacing adjustment method: changing the diameter of the road wheels

Suspension system: Three-point linkage (CAT II three-point linkage)

Hopper capacity:

180 kg (S239 model)

300 kg (model S239/1)

Operations performed in one cycle:

Furrow digging

Automatic potato planting

Ridge forming

Weight:

210 kg (model S239)

220 kg (model S239/1)

Power requirement:

28 kW / 38 HP (model S239)

32 kW / 43 HP (model S239/1)

Tractor compatibility: CAT II three-point linkage

The S239 two-row potato planter is a modern and efficient solution for farms of all sizes seeking to increase potato production efficiency. By automating the entire planting process and allowing for precise adjustment of operating parameters, this machine delivers excellent results while saving time and costs. The availability of two model variants allows for the optimal selection of the device to suit the individual needs and capabilities of the farm.

To place an order or request more information, please contact us. For questions or shipping arrangements, feel free to email us directly.

Introduction to Planters

The evolution of agricultural technology has transformed the way potato growers approach planting, with modern machines like row potato planters streamlining the entire process. A row potato planter is a specialized piece of equipment designed to simplify and speed up the planting of seed potatoes. Typically mounted on a tractor, these machines are engineered to perform several essential tasks in a single cycle: they make furrows in the soil, automatically seed the potatoes at a precise planting depth, and cover the seeded plants efficiently. This not only ensures uniform growth but also saves valuable time and labor.

For those managing larger fields, a 2 row potato planter offers the advantage of planting two rows simultaneously, significantly increasing productivity. The use of metal wheels on these machines allows for accurate control over both the distance between rows and the depth at which potatoes are planted. Potato growers can select from a range of row potato planters, including one row and two row models, to best match the scale and requirements of their operation.

When choosing a potato planter, it’s important to consider factors such as the type of tractor available, the size of the area to be planted, and the specific needs of the crop.

The link between the planter and the tractor—often a Category II three-point linkage—ensures stability and compatibility during operation. Adjustable features, such as row spacing and planting depth, allow for customization to suit different soil conditions and potato varieties. Some machines are also equipped with additional tools, like ridger blades, to further enhance the planting process.

If you have questions about which row potato planter is right for your farm, or need more detailed information about a specific product, it’s a good idea to check with the manufacturer or a trusted dealer.

Want to order?

Featured collection

-

Garlic planter AGP-4R_W GARMACH

Regular price $0.00 USDRegular priceUnit price / per -

5-ROW chain garlic planter GARMACH AGP-5R

Regular price $0.00 USDRegular priceUnit price / per -

4-ROW chain garlic planter GARMACH AGP-4R

Regular price $0.00 USDRegular priceUnit price / per -

Garlic planter AGP-3R GARMACH

Regular price $0.00 USDRegular priceUnit price / per